UK-based OTFT developer Smartkem demonstrated its first microLED display, which was produced with its own proprietary OTFT materials. The company says that its materials could reduce the cost of microLED production thanks to their low-temperature processing.

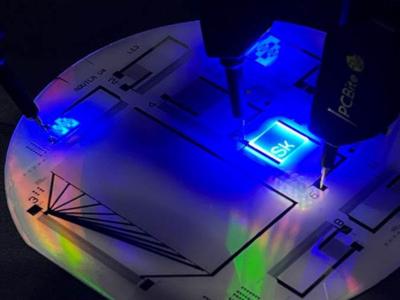

Smartkem demonstrated a sapphire wafer with arrays of 96x96 microLEDs with dimensions of 18um x 25um (produced by Enkris), planarized with Smartkem’s materials (cross-linkable polymers). Vias were then formed down to the device contact pads using photolithography and etching, and finally a metal layer was sputtered and patterned to form the anode and cathode contacts to the microLEDs. The metal connections were made selectively to generate a patterned image (see photo above).

This sample showed a static image, and Smartkem says that it is possible to further process them to turn this into an active-matrix TFT driven display though the deposition a backplane. The backplane could use Smartkem's OTFTs, using the company's chip-first, backplane-last technology. The company does update that it is continuing the development of its OTFT-backplane solution for microLEDs, and is now working to improve the yield and prove that this technology is viable and has advantages compared to laser soldering of microLEDs to contact pads (backplane first approach). The company aims to demonstrate a TFT to micro-LED connection yield of >99.999% soon, and even higher yields later on.