This is an article by TechBlick, organizers of the upcoming MicroLED Displays virtual event. MicroLED-Info readers get a 100 Euro discount.

In this article, using select technology slides, we highlight several interesting advancements in MicroLED and/or QD displays. More specifically, we cover 3600PPI “Silicon” Displays | Gravure printed microbumps | Electrohydrodynamically printed QD color converters | Laser LLO and Transfer for MicroLEDs | QD vs Phosphors | Energy saving credentials of microLED

“Silicon” Displays with an incredible 3600ppi full color using microLED and QD technology?

Sharp (HIRANO Yasuakie et al) has developed this technology.

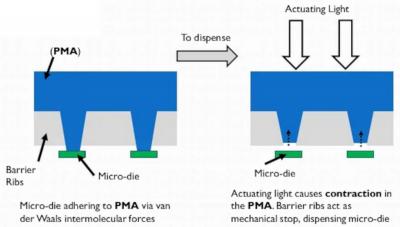

As shown in the slide below, first blue-only uLEDs are formed on a sapphire substrate. Here, one LED array contains 352 x 198 micro LED dies of 24 um x 8 um in size. In parallel, an LSI chip containing the driving circuitry is formed on a silicon wafer. Here, the cathode (N-type electrode) and anode (P-type electrode) are fabricated for each micro LED die to apply driving voltage independently to each die. The Au bump electrodes are fabricated in accordance with the pitch of the LED dies. The two substrates are flip-chip bonded using Au-Au bonding. Here one can already see the parallel to the silicon and optoelectronic industry (vs. the traditional thin film display industry!). Next, the sapphire layer is removed via laser lift off. Finally, Cd-free quantum dots (green and red) are deposited atop the microLED dies to enable R G color conversion. This way one achieves RGB colors.