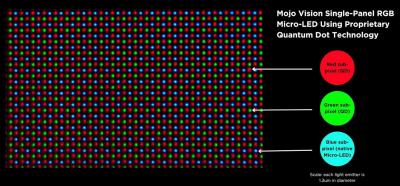

Polar Light Technologies demonstrated a red pyramidical GaN microLED array, thus achieving RGB microLEDs on the same material platform

Pyramidical GaN microLED developer Polar Light Technologies announced that it has managed to produce red (625 nm) microLEDs based on its non-etching bottom-up platform. The company now has demonstrated the production of red, green and blue pyramidal microLEDs using the same material compound.

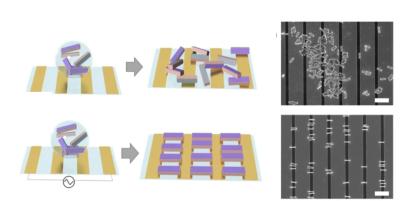

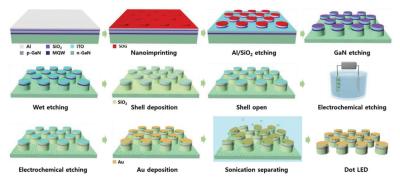

Red is the most challenging microLED emitter, and companies have been looking at several alternatives to native GaN red microLEDs, including 3D nanowires, color conversion, and color tunable LEDs. Polar Light Technologies’ microLED is composed of pyramid shapes that are built with a novel bottom-up approach, a technology that the company says comes with unique benefits, including reduced strain in the lattice of the InGaN/GaN structure, a unique possibility of frontplane integration, no etching damage (and so higher efficiency), ability to produce small microLEDs, even sub-micron, a narrow emission cone and more.