Veeco Instruments produces processs equipment for several markets, mainly the LED, PV and data storage markets.

Veeco Instruments produces processs equipment for several markets, mainly the LED, PV and data storage markets.

For the display market Veeco provides Metal Organic Chemical Vapor Deposition (MOCVD) equipment and Molecular Beam Epitaxy (MBE) products. The company's MOCVD deposition equipment can be used for microLED production, and the company sold several such systems to microLED developers.

1 Terminal Drive

Plainview, NY 11803

United States

PlayNitride orders two MOCVD systems for Veeco for microLED epiwafer production

Veeco announced that PlayNitride has evaluated its Luina MOCVD systems for microLED growth, and has now qualified it for production. PlayNitride placed an order for two systems that will be delivered in 2025

PlayNitride is building a complete supply chain for microLED production, from epiwafer production through chip processing, transfer process and more. Last year AUO announced a $21.5 million agreement with PlayNitride to build a 6-inch microLED production line at AUO's Longtan factory. Earlier in 2023, PlayNitride said that it is increasing its production volume to 10,000 6" wafers per month.

Veeco is optimistic about the microLED industry, but it does not expect any large orders until 2025

Veeco reports its financial results for Q2 2023, with revenues of $162 million (towards the high-end of its guidance) with a net income of $24 million.

Veeco says it remains committed to its microLED opportunities, as its long-term outlook on the microLED industry is positive. In the short term, however, it has sold some GaN-on-Silicon tools, but it has seen market pushing out about a year, and does not expect any significant orders until 2025.

Aledia orders Veeco's 300mm MOCVD systems for its upcoming MicroLED production fab

Veeco announced that France-based 3D GaN LED developer Aledia has selected the company's Propel 300mm HVM MOCVD system for its microLED production plant. Veeco says that the Propel system, featuring a SEMI-compliant Equipment Front End Module (EFEM) with cassette-to-cassette automation, was chosen due to its highest productivity with the lowest defectivity compared to alternatives.

Last month Aledia announced that it plans to establish a 140 million euros LED production fab in Champagnier, near Grenoble in France. The company already raised 80 million Euros and its great to see the company already ordering production equipment.

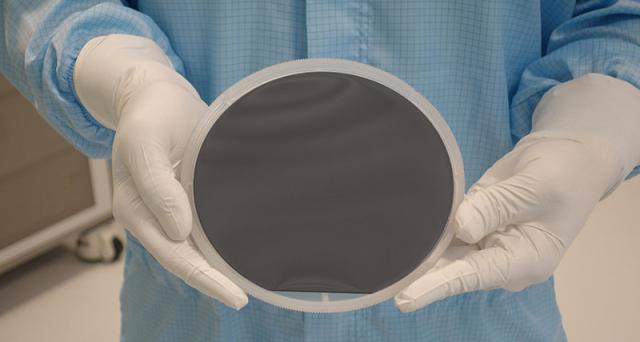

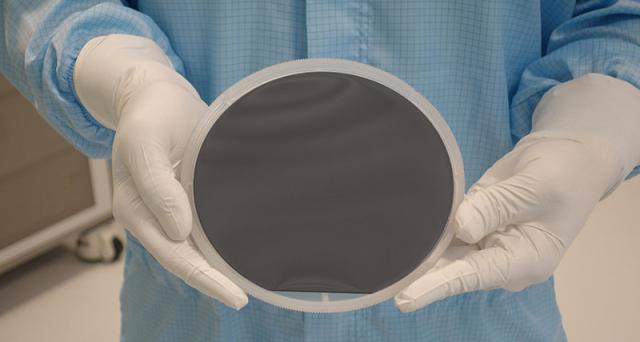

ALLOS and Veeco up-scale GaN-on-Si microLED production technology to 300 mm wafers

German-based GaN-on-Si developer ALLOS has applied its technology to large 300 mm epiwafers. ALLOS says that scaling up to 300 mm wafers enables higher production efficiencies and thus lower costs. ALLOS estimates that the higher area utilization alone accounts for a cost advantage of 40% compared to standard LED wafers. Standard 300 mm silicon line tools also offer higher production uniformity and yield.

ALLOS demonstrated the 300 mm scale-up using a reactor made by Veeco who announced selling the first 300 mm GaN reactor to a leading-edge semiconductor fab just some month ago and also showed 300 mm wafer data at CES. ALLOS reports a wavelength uniformity of consistently below 1 nm and "all other production requirements like bow of

Aledia orders more Micro-LED production equipment from Veeco

In July 2018, France-based 3D GaN LED developer Aledia announced that it has selected Veeco Instruments’s Propel GaN MOCVD system to support its advanced R&D. Veeco's Propel system enables Aledia to process 6- and 8-inch wafers or 2- to 4-inch wafers in a minibatch mode. Aledia also uses Veeco's R&D K465i MOCVD system.

Aledia and Veeco now announced that Aledia "expands its portfolio of Veeco equipment to develop and produce 3D micro-LEDs". It is not clear what kind of equipment Aledia ordered - and it also seems that the two companies are collaborating to develop next-generation Micro-LED production equipment.

ALLOS and Veeco demonstrated the reproducibility of ALLO's GaN-on-Si epiwafer technology for uniform Micro-LED production

In November 2017 Veeco and ALLOS Semiconductors announced that the two companies have completed their micro-LED strategic initiative and demonstrated 200mm GaN-on-Si wafers for blue and green micro-LED production. ALLOS proprietary epitaxy technology was transferred onto Veeco's Propel Single-Wafer MOCVD System to enable micro-LED production on existing silicon production lines.

Yesterday ALLOS and Veeco announced the completion of another phase of their mutual effort to provide the industry with leading GaN-on-Silicon epiwafer technology for microLED production. The two companies now demonstrated the reproducibility of ALLOSâ 200 mm GaN-on-Si epiwafer technology on Veecoâs Propel MOCVD reactor when producing epiwafers for many prominent global consumer electronics companies.

Aledia selected Veeco's GaN MOCVD system for large-area silicon R&D

France-based 3D GaN LED developer Aledia has selected Veeco Instruments’s Propel GaN metal-organic chemical vapor deposition (MOCVD) system to support its advanced R&D. Aledia aims to scale up its technology for large-area silicon using Veeco's system.

Veeco's Propel system will enable Aledia to process 6- and 8-in. wafers or 2- to 4-in. wafers in a minibatch mode. Aledia already uses Veeco's K465i MOCVD system.

Micro-LED microdisplay developer VueReal raises $10.5 million

Micro-LED microdisplay developer VueReal announced the initial closing of its $10.5 million Series A funding round, led by the venture arm of a large Asian company and a leading North American vendor focused on startups with emerging technology.

VueReal says that its proprietary sub-10 micrometer, high-efficiency micro-LED technology and its patented mass transfer process enables high-performance super low-power displays, coupled with a significant cost reduction.

Veeco and ALLOS demonstrate 200mm GaN-on-Si wafers for micro-LED production

Veeco and ALLOS Semiconductors have completed their micro-LED strategic initiative and demonstrated 200mm GaN-on-Si wafers for blue and green micro-LED production. Veeco transferred ALLOS' proprietary epitaxy technology onto Veeco's Propel Single-Wafer MOCVD System to enable micro-LED production on existing silicon production lines.

ALLOS says that it now has an MOCVD technology that is capable of high yielding GaN Epitaxy that meets all the requirements for processing micro-LED devices in 200 millimeter silicon production lines. Within one month the two companies managed to establish the ALLOS technology on Veeco's Propel systems and have achieved crack-free, meltback-free wafers with less than 30 micrometers bow, high crystal quality, superior thickness uniformity and wavelength uniformity of less than one nanometer.