Austria-based ams OSRAM is a multinational photonics application developer, focusing on sensors, LEDs and light-based treatment solutions.

Austria-based ams OSRAM is a multinational photonics application developer, focusing on sensors, LEDs and light-based treatment solutions.

ams OSRAM is at the forefront of microLED epiwafer production. In 2021, the company announced that it will expand its LED production plant in Kulim, Malaysia, with an investment of around $850 million, with plans to produce mini-LED and micro-LED chips on 8-inch wafers. ams OSRAM hoped to enter microLED mass production in 2024, mainly to supply microLEDs to Apple.

In February 2024, ams-Osram announced that it's cornerstone customer (Apple) cancelled its microLED project, which will have dire implications for Osram's own $850 million 8-inch microLED epiwafer factory in Malaysia - ams-Osram estimated that it will have impairment charges of $650 to $900 million and it will also likely to cancel or delay some of its investments in Malaysia.

ams OSRAM uses Aixtron's systems for LED production.

Tobelbader Straße 30

8141 Premstaetten

Austria

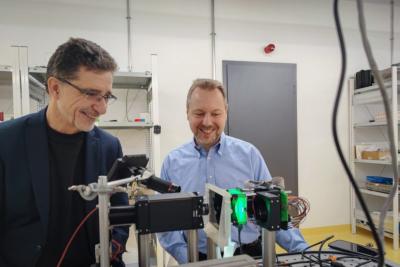

TU Braunschweig researchers, in collaboration with OUAS and ams-OSRAM are looking into using microLEDs for AI computing

Researchers at the Nitride Technology Centre (NTC) at TU Braunschweig, in collaboration with Ostfalia University of Applied Sciences and ams OSRAM, are looking into the use of microLED devices in neuromorphic computing. The researchers say that the adoption of microLED devices may lead to highly efficiency AI computers.

The basic idea is to mimic the biological neural network by using photonic components. The researchers are combining GaN components with conventional silicon microelectronics to create highly integrated arrays with hundreds of thousands of micro-LED. Using microLEDs can enable a power reduction by a factor of 10,000 compared to current technologies.

Aixtron is highly positive on the microLED industry, expects large tool orders in 2026 as producers aim to start ramping up production by 2027

Aixtron announced its financial results for Q3 2024, with solid orders and revenue, despite a slight miss on guidance due to a project delay. This project was a large order for a microLED customer, with tools shipments pushed to December instead of October.

Aixtron says that "despite the news from Apple and ams OSRAM" the microLED industry is continuing to work on the technology, and the company received orders from several customers building R&D and pilot production lines. Aixtron expects its microLED revenues in FY2024 to be at high double-digit million euros.

ams Osram announces its new microLED strategy, will mostly withdraw from the microLED display market

In February 2024, ams-Osram announced that it's cornerstone customer (Apple) cancelled its microLED project, which will have dire implications for Osram's own $850 million 8-inch microLED epiwafer factory in Malaysia. Back then ams-Osram estimated that it will have impairment charges of $650 to $900 million and it will also likely to cancel or delay some of its investments in Malaysia.

ams-Osram now announced its plans and strategy following Apple's decision to cancel its project. It seems as if the company has decided to pretty much withdraw from the microLED display market, and the only remaining microLED development efforts will focus on automotive lighting products. ams-Osram now believes that microLED displays will primarily play a role in several smaller applications that also will scale slower and later than previously expected. We also believe that microLED displays will take a longer time to mature than some in the industry have expected.

How will Apple's withdrawal impact the MicroLED industry?

A few days ago, Apple decided to cancel its microLED project with ams-Osram, a development that took the display industry by surprise. It certainly surprised ams-Osram, which announced it will have to re-assess its microLED strategy and incur $650-900 million in impairment charges. It is currently unclear whether Apple's decision was to completely abandon microLED technologies, or if it still in the microLED race, perhaps with different technologies and suppliers. It is likely that Apple does not have any immediate plans to introduce microLED displays, though. In this article, we'll try to analyze the reasons which led to Apple's decision and the probable implications for the microLED industry.

Summary:

- Apple cancels its microLED project with ams-Osram

- We estimate that the main reasons are Apple's technology choice and strategy

- MicroLED production will require next-gen technologies to succeed

- MicroLEDs still pose the best route for the future display technology, but companies will need to realign their strategies

Apple worked on microLED R&D since 2014, with a first target of producing microLED smart watch displays to replace the currently-used AMOLED displays. The Company had several partners, and decided to handle some of the process in-house. It seems as if even after almost 10 years of development and intensive R&D (estimates of Apple's total investment in microLED technology so far range between $1-3 billion USD), the technology was not ready for mass production - at least not at a price that Apple can accept.

Apple cancels its microLED wearable display project, how will this affect the microLED industry?

Apple started developing microLED displays for wearable devices years ago, first aiming to launch the first product in 2023. The project was delayed several times, as the cost of production for microLED displays was too high for Apple, to the point where it was suggested Apple's goal is to launch the first microLED watch in 2027.

One of Apple's main microLED partners is ams-Osram, that is building a $850 Million 8-inch microLED epiwafer factory in Malaysia. Yesterday ams-Osram announced that its "cornerstone project" (it did not name Apple specifically) got unexpectedly cancelled. This triggered ams-Osram to re-assess its microLED strategy. As a first estimate ams-Osram believes it will have impairment charges of $650-$900 million and it will also likely to cancel or delay some of its investments in Malaysia (which may actually improve the company's cashflow in the next two years).

ams Osram signs a $420 million sale-and-lease agreement for its Kulim microLED production site

ams Osram is progressing with its microLED production fab project in Kulim, Malaysia, and the company has now signed a sale-and-lease agreement with three local Malaysian funds, with a total sum of 2 billion RM (or about $420 million USD).

ams Osram will sell its Kulim facility (The building itself) to Permodalan Nasional Bhd (PNB), the Employees Provident Fund (EPF) and Retirement Fund (KWAP), and will lease it back for at least 10 years. The deal is expected to be formally signed by December 2023.

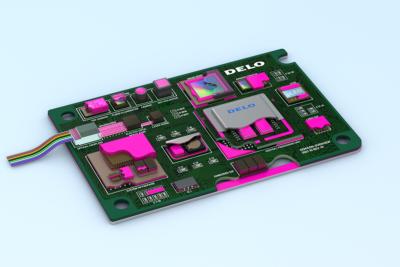

A spotlight on DELO: a MicroLED Industry Association member

We're happy to interview DELO, as part of our series of interviews with MicroLED Industry Association members. DELO is a leading maker of high-tech adhesives and other multifunctional materials as well as corresponding dispensing and curing equipment.

DELO's hightech materials come to play for numerous of semiconductor, automotive and consumer electronics applications

Can you introduce your company and technology?

Dr. Tim Cloppenborg, senior project manager: DELO is a leading manufacturer of high-tech adhesives and other multifunctional materials as well as adhesive dispensing and curing technology. Our products are mainly used in the automotive, consumer electronics, and semiconductor industries. They can be found in almost every mobile phone and in most cars worldwide, for example in cameras, loudspeakers, electric motors, or sensors. DELO's headquarters are in Windach, Germany, near Munich, with subsidiaries in China, Japan, Malaysia, Singapore, and USA, as well as representative offices and distributors in numerous other countries. We employ a workforce of 1,000 staff and achieved a turnover of almost €205 million in the last fiscal year. Our customers include Bosch, Huawei, Mercedes-Benz, Osram, Siemens, and Sony. As an innovative company, we always work ahead of the curve and pursue upcoming trends proactively. Regarding microLED applications, we are excited to provide adhesive research and expertise to our tech partners for the development of next generation displays, which will set a new standard for communication and visualization.

The German government to grant over 300 million Euro to ams-osram to support its semiconductor technology

The German federal government and the Free State of Bavaria are looking into supporting ams-OSRAM in its aim to increase its optoelectronic components R&D investment at the company's Regensburg facilities. ams-OSRAM asked for subsidies of more than 300 million Euro, which will create 400 new high-tech jobs.

ams-OSRAM will use the funds to increase its R&D efforts, build new clean rooms, labs and pilot lines. The funds will include support for several projects, including UV-C LEDs for disinfection, NIR emitters for LiDAR applications, new components to support industry 4.0 applications - and microLED display technologies. The company has already started to build a 8” wafer pilot production line for microLEDs in Regensburg.

A new report by Nikkei Asia details Apple's microLED production plans

Apple's microLED projects and goals have been reported and rumored many times in the past, and now the respected Nikkei Asia newspaper posted an interesting article with new details of Apple's microLED plans. Some parts of this plan were already published by other reporters, note.

According to the new report, Apple is aiming to get more involved in display manufacturing, to increase its control over its supply chain, and reduce its reliance on Samsung Display specifically. Apple has decided, therefore, to handle the LED transfer (pick-and-place) process by itself, at its R&D facilities in Longtan, Taoyuan, Taiwan.

ams OSRAM qualified Aixtron's 200 mm microLED production systems

Aixtron announced today that ams OSRAM has qualified Aixtron's AIX G5+ C and G10-AsP MOCVD systems on 200mm wafers for Micro LED production.

ams Osram will be using Aixtron's systmes at its upcoming 200 mm mass production line in Malaysia, which is expected to begin production in 2024.

Pagination

- Page 1

- Next page