By: Dr. Tali Hurvitz, VP Research & Development & Noam Shapiro, VP Communications, InZiv

MicroLED technology is transforming the world of displays, from AR/VR devices to cutting-edge automotive applications. However, in order for microLED to mature both technologically and commercially, precise functional inspection continues to be essential. Photoluminescence (PL) and electroluminescence (EL) are two primary techniques for evaluating microLED functionality. PL testing measures light emitted from the microLED after excitation by a laser. This excitation mechanism causes a recombination across the entire junction (usually multiple quantum wells, depending on the excitation wavelength) which in turn leads to the emission of light. In this way, PL can measure certain basic properties of functionality.

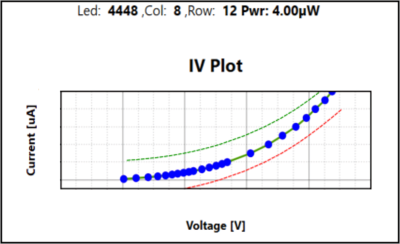

IV (current-voltage) curve being measured during EL testing of a microLED chip

On the other hand, EL testing measures light emitted when voltage is applied to the LED, and in this case, the mechanism that activates the emission of light is the electrons and holes moving to the junction. Because electrons move much faster than holes, most electron-hole recombination—and thus light emission—occurs in the region of the junction where the holes are concentrated. This method of light excitation more accurately reflects real-world performance under operational conditions; the microLED display in the final electronic device will be activated via electric current and not via light.

Research has shown that EL is ultimately the superior method, and relying on PL alone, even while calibrating for inaccuracies, is an unreliable approach that often completely misidentifies defective LEDs as functional, and severely compromises measurement accuracy. Moreover, PL also often mischaracterizes the optical power and wavelength distribution across the wafer, failing to provide reliable testing results. We will briefly summarize below some of the research that has demonstrated the superiority of EL over PL for microLED testing and inspection.