Adhesive developer and MicroLED Association member DELO has conducted in-house feasibility studies, that shows that their directional conductive adhesives can be used to replace soldering in miniLED, and microLED displays. The bonding was found to be reliable with high yields.

DELO says that current microLED displays use solder materials to interconnect the LEDs to the display backplane. But as chip size gets smaller, isotopic conductive materials (like solder) is not reliable as it is difficult to avoid short circuits, and so production yields suffer.

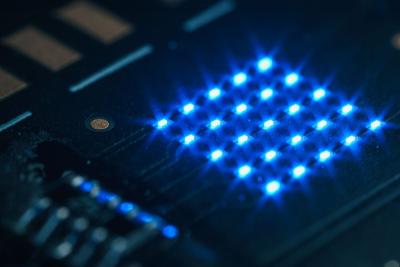

DELO has used its MONOPOX AC268 material, a directional conductive adhesive, to test the approach. The adhesive was applied by dipping the miniLED light into a reservoir of DELO MONOPOX AC268 adhesive, then thermode-cured at 180 °C for 20 seconds. Once cured, the miniLED dice were then tested for operational feasibility; one singular die was fixed to one test board while another board contained several lights in a daisy chain array. Lamps on both boards illuminated without issue, short circuits being successfully avoided.

The basic idea behind the material's use is that the adhesive contains conductive materials flakes, sparsely dispersed. As the LED is placed on the adhesive, it forces the adhesive which brings the conductive flakes closer together, thus creating a conductive material - but only in the vertical direction, exactly what is required in microLED displays.

DELO published a white paper that contains more information on this research and the full results, you can access it here.