SAPIEN Semiconductors, based in Korea, is a fabless design company that provides innovative PWM CMOS backplane and μ-driver ICs for Micro-LED displays. The company utilizes its own patented technologies to achieve lower power consumption, lower leakage, better repairability and improved testability.

In the following interview, we discuss the companyâs technology and business with its CEO, Myunghee Lee.

Q: Hello Mr. Lee, thank you for your time. Can you give us a short introduction to SAPIEN and your microLED technologies?

SAPIEN specializes in developing CMOS Backplane SoCs (System-on-Chip) for Micro-LED display applications. SAPIEN was founded in 2017 by industry veterans who have over 230 years of combined design experience in Display Driver ICs (DDI).

SAPIEN has a wide range of DDI design IPs and customizes each product based on the specific requirements for each customer. Therefore, each development will incur NRE charges to the customer. Once the product enters mass production, the NRE charge will reduce the unit price of the product.

To meet customersâ specific requests, SAPIEN owns key design patents including:

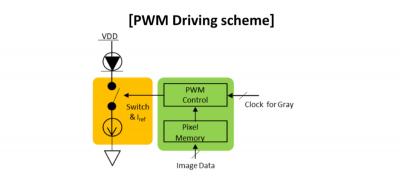

- Low-power Digital (PWM) Driving

- Patented Multi-bit MiP (Memory-inside-Pixel)

- Worldâs best power efficient high-speed serial Interface IP such as MiPi and eDP

- Low-power Compression IP

- Lite De-Mura compensation IP

Q. We understand you use PWM-based driving circuits, which helps to lower power consumption. Can you share more details on how PWM conserves power?

Each pixel of the CMOS backplane SoC contains a multi-bit SRAM cell (for example, a 10 bit SRAM cell for supporting 10-bit color depth) and a combination logic circuitry to generate a specific PWM pulse stream. The memory content of each pixel is updated frame by frame, and the pixelâs microLEDs are driven by a PWM pulse with a constant current source. This whole operation is carried out primarily by a digital circuit without any analog circuitry, which consumes a significant static power.

Q. What kind of power consumption and efficiency should micro-display developers expect when using your PWM CMOS backplane technology?

The power consumption depends on the display resolution, image contents and the driving current to each LED. Most of the CMOS backplane function relies on digital operation rather than analog operation. Therefore, there is minimal static power consumption. SAPIEN also owns a high-speed serial interface IP such as MIPI D-PHY which has the best power efficiency.

Q. There are other microLED backplane technology developers, what sets SAPIEN apart?

SAPIENâs engineering team brings valuable know-how to its micro-LED CMOS backplane design from our vast experience developing the most advanced LCD/OLED display driver ICs. This helps us provide optimal solutions to our customers.

SAPIEN also provides comprehensive solutions to our customers with a variety of display image processing and compensation algorithm IPs for micro-LED displays.

CMOS Backplane SoC

CMOS Backplane SoC

Q. Is SAPIEN's technology applicable for TFT displays (not CMOS based?), or other types of backplanes?

By adopting the same concept to a CMOS-based micro size pixel driver, SAPIENâs multi-bit MiP scheme can be applied to larger sized displays such as FALD-BLU (Full Array Local Dimming Backlight Unit) and Signage/TVs. Along with a 3-dimensional hybridization scheme, hybridized LEDs on a CMOS driver can be placed into any type of substrate.

Q. We know that SAPIEN also develops ICs for AMOLED displays. Can you share some information on that product line?

SAPIEN sees Micro-LED technology as the next generation display technology. Even though most of our design IPs can be applied to AMOLED driver ICs, we are focusing all our energy on micro-LED display applications.

Q. Many people believe that microLED technology will greatly enhance microdisplay performance compared to LCoS and microOLED. Do you share this view?

SAPIEN is only supplying DDI solutions to our customer. We do not compete with our customer who builds microLED display modules. Therefore, we donât have our own data to answer this question. However, most of our customers who have investigated LCoS and microOLED solutions have stated that existing solutions fall short of meeting their needs.

Q. SAPIEN is a fabless company, can you share details on your fab partners?

We use various silicon foundries such as TSMC, Jazz, Global Foundries, and Samsung based on the needs of the customer.

Q. Can you share any details on your current customers or partners, or any microLED projects you are involved with?

Due to NDAs with our partners, we are unable to share the identity of our customer. However, we can say that we are closely collaborating with global top-tier IT companies.

SAPIEN is serving display module companies as well as set makers.

Unlike the LCD or OLED display industries, where the display panel suppliers control the supply chain, the micro-LED display industry has a completely independent eco-system which creates opportunities for new players like SAPIEN.

Q. How do you see the microLED display market in the next few years? Which market segments will benefit most from microLED?

Considering the readiness and technological maturity of the mass production (or transfer technology), we believe that the large display and micro display market will be the first beneficiary, with sizeable volume in the next few years.

As you may know, Apple released its most recent iPad Pro with local-dimming mini-LED backlights this year. This is an indication that LCD displays will gradually adopt FALD-BLU in order to provide better display quality. We believe that micro-LED will eventually replace mini-LED thanks to its advantage in overall cost, power efficiency, & flexible form-factor.

The second wave would be XR(AR/VR/MR) applications. According to our customerâs input, mass production for AR applications is expected to start in early 2023.