Researchers from Korea's Kookmin University have developed a new GaN-based fin-LED chip material and pixel process technology, saying that this innovation may be the key to overcome the limitations of current microLED technologies.

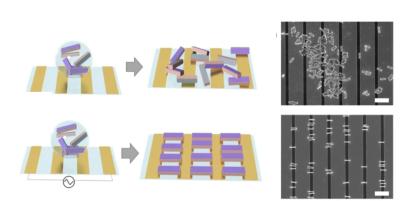

The researchers developed a viable pixel manufacturing process that vertically assembles sub-micron-sized fin-LEDs using a face-selective dielectrophoresis (DEP) assembly method. The GaN-based sub-micron-sized fin-LEDs are designed to maximize performance while minimizing costs related to the chips and pixelation process. This technology significantly enhances extraction light efficiency by vertically aligning the fin-LEDs, and it enables the implementation of chip materials and pixel manufacturing processes that significantly reduce production costs.

The lead researcher, Prof. Young Rag Do, says that compared to the nanorod LEDs of a similar size previously reported by Kookmin University and Samsung Display Company (SDC), the new fin-LEDs demonstrate a substantial performance improvement, with the volume of the multiple quantum wells (MQW) increasing by about 8 times. This leads to a marked enhancement in front-directional brightness and luminous efficiency.

The dielectrophoretic assembly method achieved a high vertical alignment rate of 91.3% and an excellent pixel production yield of 99.93% with an ink-dropping process. The blue fin-LED achieved an EQE of 9.1% and a brightness of 8,640 cd/m² at 5.0 V, demonstrating performance comparable to or surpassing existing technologies despite being in its initial stage. These fin-LEDs can be massively produced through top-down etching and electrochemical-sonochemical separation technology, maintaining a stable wafer utilization area ratio of over 90%.