This is a guest article by Dr. Reza Chaji, founder and CEO, VueReal

Imagine a future where your smartwatch evolves from a timepiece to a powerful digital hub, seamlessly integrating all aspects of your life. The potential for smartwatches to become central to daily routines is immense, especially with AI and cutting-edge technologies.

These advanced technologies enable smartwatches to support seamless communication, health and fitness tracking, environmental awareness, biometric security, and more. As a result, smartwatches are becoming indispensable tools that enrich our lives and enhance our health and security in an interconnected world.

Smartwatches must attain higher power efficiency, brightness, and additional functionalities to achieve this advanced role. This drives the demand for display technology that offers reliable performance without compromising battery life or longevity and supports the integration of other devices, such as microsensors, in-display biometrics, advanced pixels, and power scavenging functions.

In today's wearables market, OLED displays have dominated as the preferred choice for manufacturers. However, a formidable competitor is emerging: microLED technology. Contrary to common misconceptions, microLED offers several distinct advantages, positioning it as a superior alternative to OLED.

OLED Faces Challenges as MicroLED Rises

Combining material improvements, device structures, and optical enhancements can lead to low power consumption in OLEDs. However, new advancements, such as stacked device structures, have significant cost implications, hindering throughput and yield. For example, while a stacked OLED device can improve power consumption by 20% to 40%, it can also reduce the throughput of OLED deposition by half.

In another example, the POL-Less process significantly increases the number of process masks, leading to higher costs. Furthermore, some of these solutions can cause optical performance challenges for higher-resolution devices. For instance, stacked devices can lead to cross-talk at high resolutions for watches and phones, while the absence of a polarizer can result in lower contrast performance. Therefore, most of today's displays for smartwatches and smartphones use polarizers and a single stack.

While OLED technology has made significant strides in power efficiency, particularly in smartwatches and smartphones, it faces a plateau as production costs and complexity increase. Though noteworthy, OLED's advancements will eventually hit the ceiling due to the intricate structures required for further improvements.

In contrast, MicroLED technology is rapidly evolving, promising a significant reduction in power consumption. As these advancements continue, the gap between MicroLED and OLED power efficiency will widen, positioning microLED as the superior choice for future wearable displays.

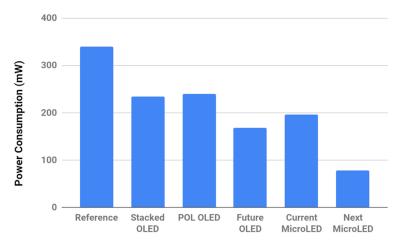

Figure 1: Smartwatch power consumption (1500 nits).

OLED display power consumption has significantly improved and is projected to reach a low value of 180mW in the near future for a display with 1500 nits. However, microLED displays still offer lower power consumption, and with planned developments, they should consume half the power of advanced OLED displays.

Brightness: Unmatched Luminance and Longevity

A significant challenge with OLED displays is their inability to maintain high brightness levels for extended periods, especially outdoors. At high brightness, OLEDs are prone to burn-in and degrade more quickly, resulting in reduced performance over time. In contrast, microLED displays excel, providing much higher brightness without compromising lifespan.

MicroLED’s superior brightness and longevity are especially beneficial for wearable devices in various lighting conditions. Whether in direct sunlight during outdoor activities or in dimly lit environments, the enhanced luminance of microLEDs ensures that smartwatch displays remain clear and readable. This is essential as smartwatches become increasingly integral to daily life.

As smartwatch functionality expands, the need for displays that perform reliably in all lighting conditions becomes increasingly critical. Features such as on-wrist navigation, augmented reality, and outdoor fitness tracking require bright and durable screens. MicroLED technology meets these demands with its unparalleled luminance and longevity.

The Cost-Effective Future of Smartwatch Displays

Many perceive OLED displays as more cost-effective due to their mature technology, recent advancements come with added costs as they require additional materials, complex structures, and integration processes. For instance, the stacked OLED structure reduces throughput and increases fabrication costs.

Initially, microLED technology's manufacturing costs may be higher due to the complexity of the expenses associated with microLEDs, transfer processes, and repairs. However, advancements in production techniques and economies of scale drive these costs down.

Innovations like MicroSolid Printing enhance material cost by improving wafer utilization efficiency and enabling the integration of small-pitch micro LEDs. Additionally, the high throughput, high yield, and scalability associated with MicroSolid Printing reduces capital expenditure and operational costs. Furthermore, new, unique, small flip-chip devices reduce material and integration costs by eliminating the need for post-processing. This unique combination leads to a cost-competitive display that outperforms and enables groundbreaking functionalities.

Manufacturing and Scalability: MicroLED Poised for Rapid Adoption

Contrary to the perception that microLED manufacturing is challenging, the technology will democratize the supply chain. Leveraging existing display supply chains and innovative MicroSolid Printing techniques, smartwatch manufacturers can rapidly scale microLED production to meet growing demand. This adaptability is essential as the wearables market expands, requiring efficient and high-volume production capabilities.

MicroLED technology offers high material utilization efficiency, significantly reducing waste compared to OLED production–minimizing the need for extensive and costly supply chains and resulting in more streamlined and cost-effective manufacturing processes. As production techniques continue to advance, scaling microLED displays becomes increasingly feasible.

MicroLED technology's compatibility with existing semiconductor fabrication infrastructure further enhances its potential for rapid adoption. This compatibility enables manufacturers to incorporate microLED production into their current facilities without extensive retooling or significant investment, facilitating a smoother transition from OLED to microLED.

Beyond Displays: Multifunctional Capabilities of MicroLED

Unlike OLED displays, which are limited to display functionalities, microLED technology offers the potential for integrating additional functionalities within the display itself. MicroLEDs can incorporate multi-sensing capabilities, advanced power scavenging structures, and more, transforming the display into a multifunctional component. This integration opens up new possibilities for wearable devices, enhancing their capabilities and providing users with more advanced features.

Sensor Integration for Advanced Wearable Solutions

MicroLED technology enables the seamless integration of sensors beneath the display without compromising display performance. This capability allows for more sophisticated wearable solutions, transforming smartwatches into independent hubs for future AI-enabled applications. Integrating sensors under the microLED display paves the way for more advanced and versatile wearable devices, from health and fitness tracking to communication.

The Path Forward

As wearable technology continues to evolve, adopting microLED displays will be vital in enhancing the capabilities and performance of these devices. With superior power efficiency, increased reliability, cost-effective solutions, and multifunctional capabilities, microLED technology will to revolutionize the wearable display market. Innovative processes and advancements like MicroSolid Printing are at the forefront of this transformation, paving the way for a future where wearable devices are more powerful, efficient, and versatile than ever before.