Researchers from Seoul National University, in collaboration with LG Electronics, developed a new transfer process for microLED displays, based on a fluidic process.

The new process, called Fluidic Self‑Assembly (FSA), starts with a collection of microLEDs (chiplets) dispersed in an assembly solution, and a display substrate in which the binding targets are coated with molten solder. The substrate is immersed in the fluid, and then the fluid is set in motion (is shaken), which causes the microLED chiplets to make repeated contact with a binding targets. When a microLED chiplet meets the binding target, surface tension induces an irreversible bond between the solder and a metal electrode on the chiplet.

This is a very simple process, but the researchers say it has high potential as it can simultaneous assemble many chiplets. This method is known for many years, and more than 20 years ago about 1,500 components around 300 micrometres across were assembled using the method. The researchers applied FSA to microLED chiplets.

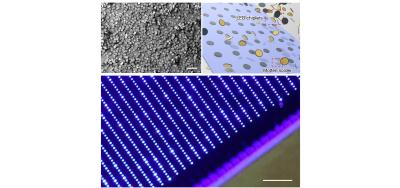

During their first testing, the researchers discovered that the assembly yield decreases substantially when the chiplet size falls below 100 μm. It was found that to assemble sub‑50‑μm chiplets with a high yield, they had to increase the momentum transferred from the assembly solution to each chiplet. The researchers accomplished this by raising the viscosity of the solution, by adding a polymer known as poloxamer. This has the added advantage that it can remove any microscopic bubbles or small particles that might be on the surface of the binding sites and could decrease the assembly yield by impeding close contact between the chiplets and the solder. By incorporating a small amount of poloxamer into the FSA process, the researchers produced a lighting panel consisting of more than 19,000 microLED chiplets, each emitting blue light and having a diameter of 45 μm. These chiplets were assembled with a yield of 99.88% using only one minute of vigorous manual agitation.

Fluidic-based processes are promising, and we know of at least one company that commercializes a fluidic self-assembly of microLED displays, US-based eLux.