How XTPL's Ultra-Precise Dispensing System is Shaping the Future of OLED and MicroLED Displays Exploring the Future of Display Technology: OLED, QD-OLED, and MicroLED Compared

OLED (Organic Light-Emitting Diode), QD-OLED (Quantum Dot Organic Light-Emitting Diode), and MicroLED (Micro Light-Emitting Diode) share some common characteristics as emissive display technologies:

- Emissive nature: They all emit light when an electric current is passed through them.

- Active matrix: They use an active matrix to control the emission of each pixel.

- Pixel structure: Each pixel typically consists of three sub-pixels (red, green, and blue) that can be controlled independently.

- High contrast ratio: They are capable of producing high contrast ratios due to their ability to turn off or dim individual pixels.

- Fast response time: They have fast response times, which enables them to display fast-moving content without blurring or ghosting.

- Viewing angles: They can maintain good color accuracy and contrast even when viewed from the side, although MicroLEDs tend to have better viewing angles.

Fig. 1 XTPL Ultra-Precise Dispensing System

XTPL's Ultra-Precise Dispensing Technology: Revolutionizing New-Gen Display Manufacturing

New-gen displays require tomorrow’s microtechnology troubleshooting. This is where XTPL steps in with its Ultra-Precise Dispensing technology. In response to the market needs, they offer two devices for two different ways of working. Delta Printing System (DPS) is mostly dedicated to work in an R&D environment, as a stand-alone, open platform for prototyping and low-scale production. On the other hand, Ultra-Precise Dispensing technology, the core of DPS, is a configuration tailored and adjusted to customer requirements for integration with industrial equipment or/and production lines.

Speaking of new-gen display applications and common struggles, Ultra-Precise Dispensing offers a set of feature technologies:

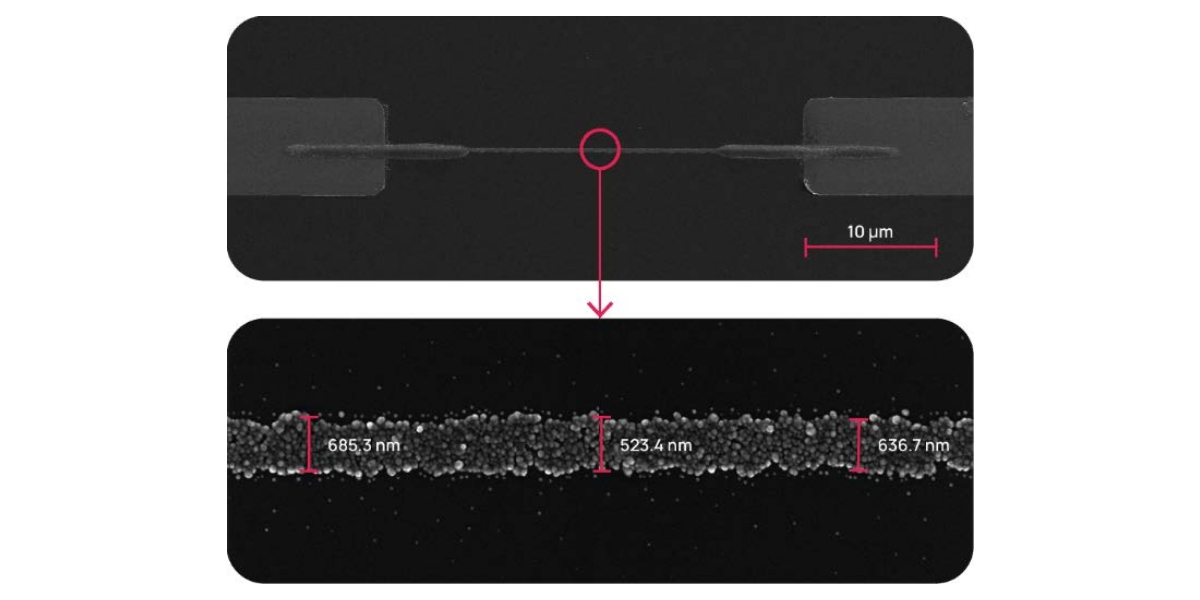

- Open defect repair application for improving yield management of OLED, Mini and microLED, and micro OLED displays

Fig. 2 Open Defect Repair

- Filling the cavities with Qdots ink to increase the resolution for microQLED

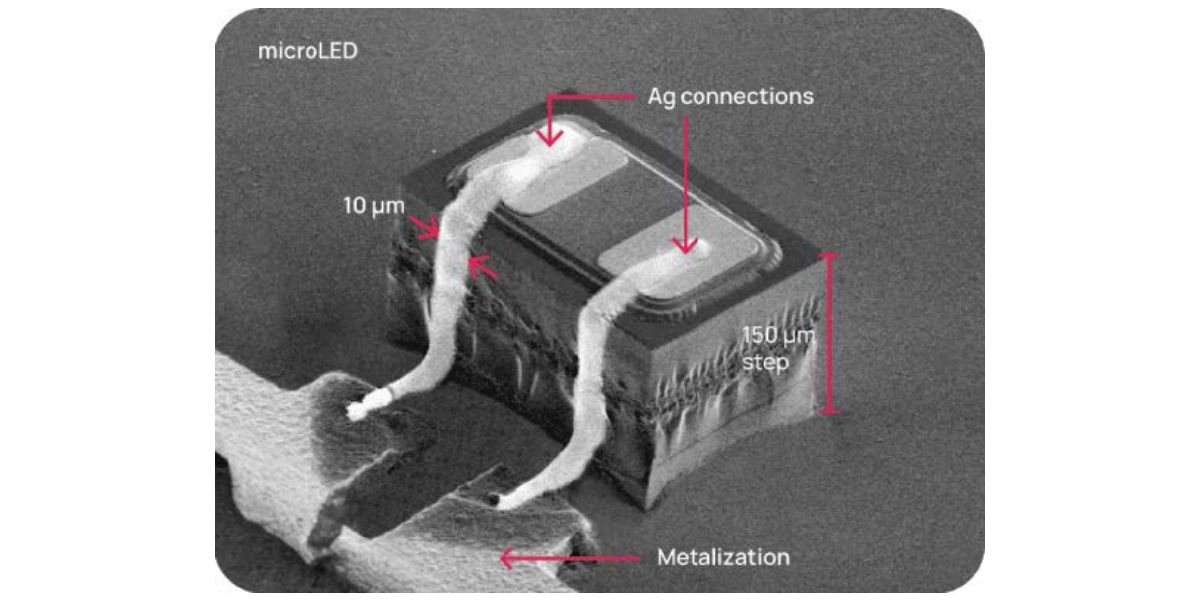

- 3D conductive interconnections for mini and microLED displays

Fig. 3 3D conductive interconnections

- High-precision conductive edge interconnections for electrodes on the opposite sides of substrates for new-gen AR/VR displays

- High precision dispensing of micro-bumps for microLEDs attach

- Alignment marks (fiducials) dispensing for display glass

Along with devices, XTPL provides its users with conductive nanopastes and nanoinks based on gold and silver. Briefly, it is a one-shop-stop supplier for a whole range of enterprises.

For more information, contact XTPL here

This was a sponsored post by XTPL