A 200 mm microLED R&D and low-volume production line is being sold in Europe

A state-of-the-art GaN production facility in Europe has been put up for sale. As per the seller, the facility offers extensive GaN capabilities as well as a track record of doing high-volume CMOS production. The facility include 40,000 sqft of cleanroom space, and about 200 process tools (80% of which are 200 mm). This facility is currently engaged in R&D development and low-volume micro LED manufacturing with existing profitable revenue. The identity of the seller has not been published.

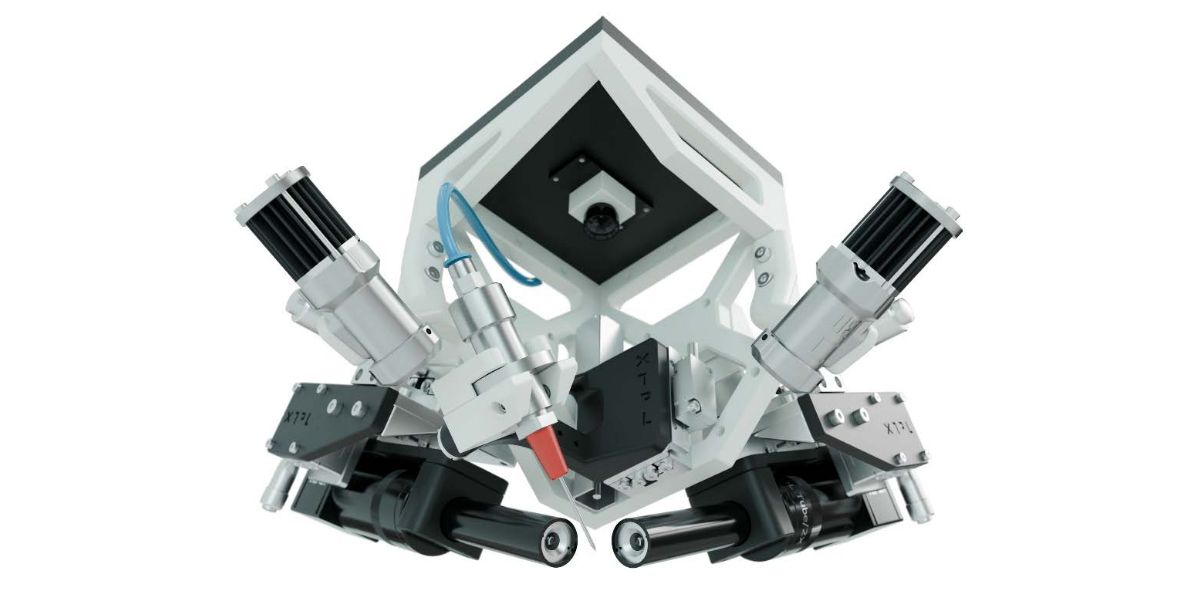

The sell has exclusively retained ATREG to handle the sale. ATREG says that the facility is offered with a comprehensive IP portfolio, over 250 skilled employees (of which 110 are engineers), and specialized capabilities in MOCVD, CMP, and wafer bonding. In addition to the current micro LED capabilities, the fab is suited for GaN power devices, advanced photonics, GaAs processing, and MEMS/sensors manufacturing. The fab has received significant investment over the past five years, including sub-fab upgrades, cleanroom expansion, utility improvements, and other facility upgrades.