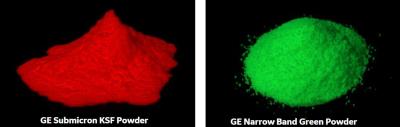

We're happy to interview GE, as part of our series of interviews with MicroLED Industry Association members. GE offers narrow band red and green phosphor technologies known as KSF and PFS, suitable for microLED color conversion.

Can you introduce your company and technology?

Rachel Cassidy, PhD, MBA: The General Electric Company (GE) is an American multinational company. For more than 125 years, GE has invented the future of industry. Today, GE is best known for its work in the Power, Renewable Energy, Aviation and Healthcare industries.

GE’s Licensing team provides access to GE’s patent portfolio and technical and intellectual resources. Licensees receive world-leading technology paired with advice and guidance to accelerate their technology development and achieve market differentiation.

The GE LED Phosphors team has world class chemistry and physics expertise as well characterization capabilities that have resulted in commercial successes in both lighting and LCD display technologies. Multimillion-dollar yearly revenue, multiple awards, hundreds of patents, over 20 licensees of our patents, along with various publications and invited conference presentations show that this team is on the cutting edge of luminescent material development and can advance from concept to invention to commercialization. Our narrow band red phosphor technology known as KSF (K2SiF6:Mn) can be found in over 60 billion LEDs as well as remote films for miniLED applications sold into the display industry. The great success of KSF phosphor in the display industry is due to the high color gamut and energy efficiency that has best in class reliability.

Can you say why you joined the microLED association and what it is you hope to achieve?

GE joins the microLED Industry Association to help promote our phosphors innovations for microLED display technologies. We now have highly absorbing, submicron KSF phosphor that we have incorporated into inks, and we have developed printing capabilities using these inks to help build out the value chain in this newly emerging market sector.

What is your biggest challenge, and success to date in the microLED industry?

The GE LED Phosphors team has reduced the particle size of our commercially successful KSF/PFS (Potassium Fluorosilicate) phosphor to a submicron size so that it may be incorporated into ink formulations and printed via various printing techniques such as inkjet printing, DR Blade printing, etc. Correcting misinformation that we become aware of in the industry regarding KSF/PFS and fast response time displays is also important to the team. KSF is already in many commercially available full-array local dimming televisions and high refresh rate gaming laptops and monitors (440 Hz refresh rate with 1 ms response time), with more in development and soon to be on the market with even faster refresh rates. As opposed to QDs, KSF has high EQE in unencapsulated architectures due to its much better reliability.

Can you detail your latest prototype/demonstration?

The GE LED Phosphors team is printing KSF on microLED arrays and color filters with outstanding reliability and color quality. We plan to be able to share more on this in the coming year.

How do you see microLEDs changing the display industry in the next 5-10 years?

The value chain for microLEDs continues to evolve and grow, with the well-known microLED companies leading the charge. The GE LED Phosphors team is well prepared to provide wide color gamut color conversion solutions for microLEDs as we are, and have been, actively building out the value chain by becoming more vertically integrated. The team’s focus on phosphor powder has advanced to ink formulation and printing. The next 2-5 years will be an exciting time to watch the microLED market unfold. We welcome inquiries and partnering opportunities.