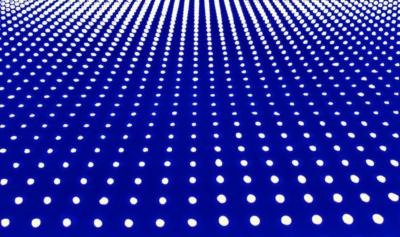

Samsung faces technical issues and will have to delay the launch of its true microLED TVs

According to reports early in 2020, Samsung Electronics partnered with Epistar and PlayNitride that will enable Samsung to release its first true microLED TVs by the end of 2020. A new report from Korea suggests that Samsung is struggling with technology issues and it is not likely it will meet its goal of a product release in 2020.

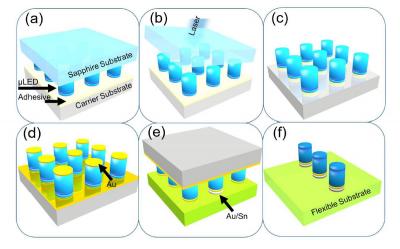

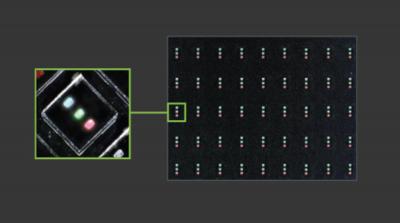

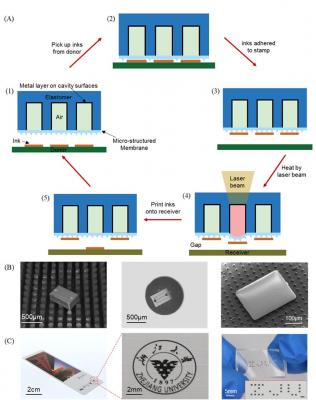

The reports suggest that production yields are very low - apparently Epistar is not able to provide Samsung with the millions of microLEDs required to produce its TVs. Another major issues is Samsung's transfer process which is still not accurate enough - with the result being that display assembly yields are painfully low.