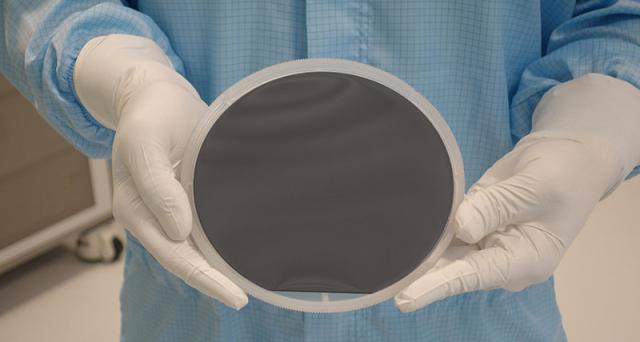

Jasper Display unveils a new silicon wafer specialized for micro-LED displays

Taiwan's Jasper Display Corp (JDC) unveiled its new silicon micro-LED backplane, the eSP70, which reportedly features high brightness and contrast possible. JDC's eSP70 is capable of FHD (1920x1080) resolution using a pixel pitch of 8 um and JDC says that it offers excellent current uniformity via a proprietary current source pixel (uniformity is better than 1% across the array).

Taiwan's Jasper Display Corp (JDC) unveiled its new silicon micro-LED backplane, the eSP70, which reportedly features high brightness and contrast possible. JDC's eSP70 is capable of FHD (1920x1080) resolution using a pixel pitch of 8 um and JDC says that it offers excellent current uniformity via a proprietary current source pixel (uniformity is better than 1% across the array).

JDC demonstrated the eSP70 using micro-LEDs provided by glÅ. The company says that this is the industry's first specialized micro-LED ready silicon. JDC's technology can be customized and it can be suitable for a wide range of applications, from AR headsets to automotive headlights. JDC's eSP70's 8" are now shipping.