Vuereal announces a partnership with ASMPT to integrate the company's transfer and bonding solutions

Canada-based microLED technology developer VueReal announced a partnership with ASM Pacific Technologies (ASMPT) to integrate VueReal's cartridge microLED mass transfer solution into ASMPT's mass transfer bonding solution for microLED display applications.

Vuereal says that this new partnership will allow its customers to achieve 99.99+% transfer yields on LED's smaller than 10 micrometers.

VueReal demonstrates high yields and low cost LED flipchip process

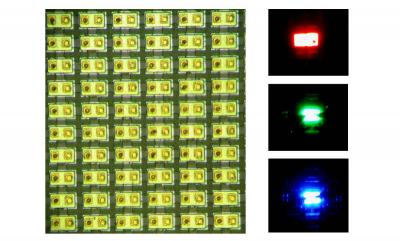

VueReal announced that its patented flipchip structure demonstrated higher yields and lower costs compared to standard vertical LED process.

The company says that flipchip processes are favored by display makers, due to the easy integration they offer. Most processes, however suffer from low yields and a complex process. VueReal's process has achieved yields higher than 99.9%, and with a more automated fabrication line can even achieve higher yields.

We talk MicroLED displays with VueReal's CEO

Canada-based VueReal is a startup company that develop Micro-LED based microdisplays. The company's Continuous Pixelation micro-printing technology offers high density displays, high production yields and a simple design.

VueReal's founder and CEO, Reza Chaji, was kind enough to answer a few questions we had on the company's technology and business.

Reza, thank you for your time. Can you explain VueReal's micro-printing process and technology?

VueReal’s solution is a true printing process where you do not need to pick LEDs for each transfer. It is based on a cartridge design by VueReal that releases the LEDs selectively into the substrate.

VueReal developed a 30,000 PPI micro-LED microdisplay, will start accepting orders for samples soon

Micro-LED microdisplay developer VueReal will start accepting orders for its first micro-LED display samples by June 2019. The company says that its patented self-aligned technology resulted in a robust and high yield microdisplay production process.

VueReal says that it developed Micro-LED microdisplays that achieve a brightness of 100,000 nits and a density of over 30,000 PPI - breaking its own world record of 6,600 PPI set in 2017.

In October 2018 VueReal announced that it has raised $8.5 million and that it will build an advanced nano technology fabrication center in Waterloo, Canada - which will include an integrated pilot production system that will use the company's proprietary sub-10 micrometer, high-efficiency, solid printing process at commercial volumes.

VueReal raised $8.5 million, to build an advanced fabrication center in Canada

Micro-LED microdisplay developer VueReal announced that it has raised $8.5 million from Sustainable Development Technology Canada (SDTC) that will be used to further develop its technology. VueReal will also build an advanced nano technology fabrication center in Waterloo, Canada, in partnership with Angstrom - a Canadian-based PVD and CVD equipment maker.

VueReal says that its next step is to build an integrated pilot production system that will use the company's proprietary sub-10 micrometer, high-efficiency, Solid Printing process at commercial volumes. The company will also work to enhance the performance of its Micro-LED microdisplays.

Micro-LED microdisplay developer VueReal raises $10.5 million

Micro-LED microdisplay developer VueReal announced the initial closing of its $10.5 million Series A funding round, led by the venture arm of a large Asian company and a leading North American vendor focused on startups with emerging technology.

VueReal says that its proprietary sub-10 micrometer, high-efficiency micro-LED technology and its patented mass transfer process enables high-performance super low-power displays, coupled with a significant cost reduction.

Pagination

- Previous page

- Page 3