Researchers from Xerox PARC have developed a new micro-transfer printing technique that can be used to mass-transfer microLED devices. This technology offers high performance, simple and robust structure, and high process scalability and flexibility.

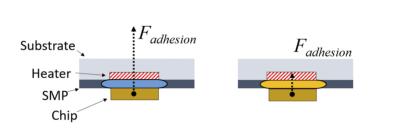

The new technology uses thermally induced adhesion modulation of shape memory polymer (SMP) materials. The idea is to use a print head that uses an individually-addressable micro-fabricated resistive heater array, which locally delivers heat for transfer of single microLED devices.

The researchers demonstrated the new technology, and have transferred chips with a size of 50x50 um, with a pixel pitch of 100 um. The transfer head can be dynamically configured to assemble micro-objects in arbitrary patterns, allowing digital manufacturing, object sorting, or in-line assembly correction of defects.

The transfer-printing head (shown above) comprises of a glass substrate, a micro-heater array, and a controllable adhesion layer, which is made of SMP.