Researchers from the University of Strathclyde develop a continuous roller microLED transfer-printing process

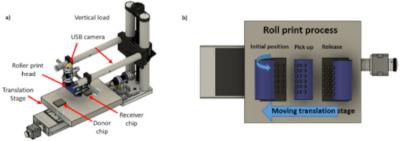

Researchers from the UK-based University of Strathclyde, led by Dr. Eleni Margariti, developed a new microLED transfer process, based on a continuous, single shot roller transfer printing process.

The researchers say that this process can enable large-scale integration of microLEDs. The system they developed can transfer an array of 320x240 pixels (over 75,000 microLEDs) in a single shot, with sub-micron relative position accuracy. The transfer printing process preserves the array geometry with pixel spatial location error less than 1 µm deviation from the as-designed layout.

The researchers also employed an automated sub-micron precision metrology system based on simple optical microscopy, to asses such large device populations and allow the assessment of yield.