MicroLED transfer technology explained

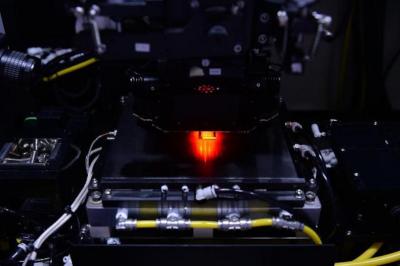

The microLED transfer process is crucial in MicroLED display production, this is likely to be the most challenging part of the entire process. In this article (an excerpt from The MicroLED Transfer Process Report), we'll give an overview of the transfer process, its challenges, and alternatives.

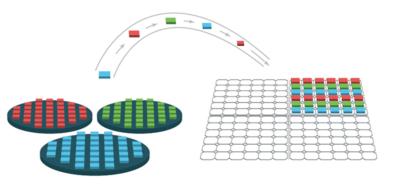

At the beginning of this stage, there's the wafer with the MicroLED chips, and a display substrate with the backplane TFTs on top. As we said, this is a challenging process, and there are three main challenges in this step – accuracy, speed and reliability.

It is important to note that if the display is based on RGB microLED devices, it complicates this step further – which is why many MicroLED makers are expected to adopt blue LEDs with color conversion.