This is a sponsored post by Coherent

Coherent is a leading global supplier of lasers and photonics technology. For the MicroLED industry, Coherent provides several solutions from a single laser source, optical systems up to an integrated system for the three vital processes in MicroLED fabrication – Laser Lift-Off (LLO), Laser-Induced Forward Transfer (LIFT), and Repair/Trimming.

Coherent recently published a new white paper that provides an update on how high-energy ultraviolet laser beams enable LLO and LIFT processes. The white paper shows the importance of a perfect combination of laser and optical design to a how these lasers ensure placement accuracy and mass transfer that will remain future-proof as microLED chip die size continues to shrink.

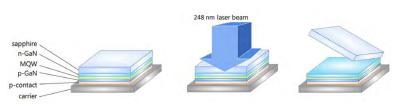

Schematic of a LLO process for the delamination of GaN film from sapphire wafer

The white paper provides a very nice introduction into microLED production processes, with a focus of course on the role of lasers during the various process steps. Coherent provides an in-depth discussion on the LLO and LIFT processes, along with its latest achievements in these steps. Finally, the paper also discusses the need for repair or replacement of defective LEDs and how the company's lasers solutions can be used to solve this crucial production issue.