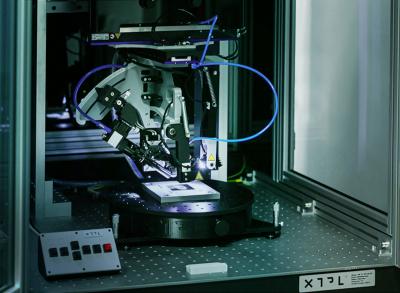

We're happy to interview 3D Micromac, as part of our series of interviews with MicroLED Industry Association members. Germany-based 3D-Micromac is the industry leader in laser micromachining and roll-to-roll laser systems. The company offers laser equipment for µLED forward transfer, lift-off and repair process steps - ready for high volume production.

Hello, can you introduce your company and technology?

Frank Richter (Head of Sales at 3D Micromac): 3D-Micromac has established itself as a leader in laser micromachining and a pioneer of new production technologies for various industries for the last 20 years. This especially applies to the excimer and ultra-short pulse laser technology.

We have extensive experience applying innovative laser technology to new and emerging applications to support their volume-production requirements. For MicroLED production, ultra-high precision in combination with the highest reliability and stability is needed. These are core competencies of 3D-Micromac.

Our product portfolio includes several laser-based system solutions for various manufacturing steps in the MicroLED production process. All systems offer integrated process control and monitoring to assure stable and reliable operation, thus enabling high throughput and low yield losses.