Applied Materials Baccini Cell Systems provides advanced screen printing solutions for microLED production

This is a sponsored post by Applied Materials

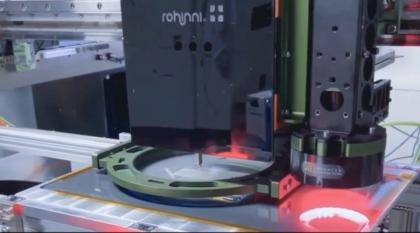

Applied Materials Baccini Cell Systems provides advanced screen-printing solutions and systems for a wide range of applications - including for MicroLED production.

Here is an interview we conducted with Applied Materials' Director of Global Product Marketing, Daniel Hada, who details the company's solutions for MicroLED production and R&D.

Q: Can you tell us a little bit about Applied Materials' Baccini systems? What kind of systems are you offering?

We provide advanced screen-printing solutions for both R&D applications and high volume manufacturing. All Baccini systems are built for sheet-to-sheet printing, either on flexible or rigid substrates. In addition to our screen-printing capabilities, we also provide customers with different drying and curing solutions, in-line inspection systems to monitor the quality of the print immediately after the print, and fully automated print lines to enable low cost, and high volume manufacturing. Utilizing Baccini’s Esatto technology which provides high accuracy and high print repeatability, we developed the Double Print technology years ago, to allow print on print capability for printing narrow lines/small features with high aspect ratios and to minimize interruptions in the printed lines.